Mills Peninsula Hospital

In the beginning…

Due to its complexity, the decision was made to utilize Building Information Modeling tools to first build Mills in virtual space prior to any physical construction.

Mills Peninsula Hospital began, in 3D, on this screen.

|

| From Drawings |

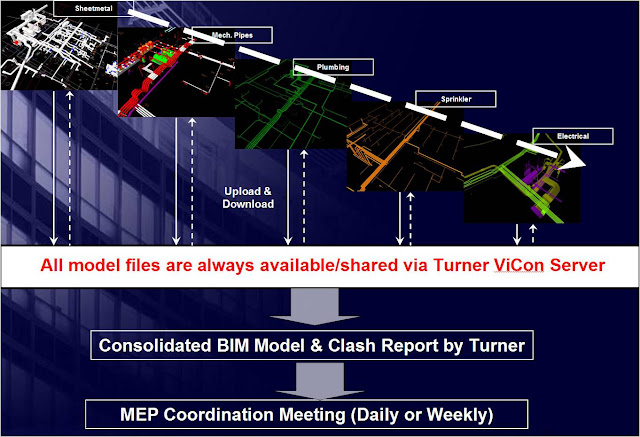

After each sub modeled their own system, the files were consolidated in Navisworks, merged with architectural and structural models, and coordinated with one another to bring the building to life.

|

| From Drawings |

The sprinkler model looked like this

|

| From Drawings |

The electrical model looked like this

|

| From Drawings |

The plumbing and med-gas model looked like this

|

| From Drawings |

The mechanical model looked like this

|

| From Drawings |

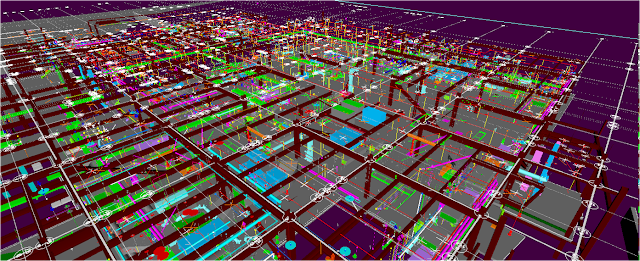

And combined with the architectural and structural models, the consolidated model looked like this

|

| From Drawings |

Clash detection took place on a tri-weekly basis and conflicts were identified and coordinated

|

| From Drawings |

Now it starts to get really cool…

Because the building is base isolated and can move up to 30″ in any direction, we were able to model seismic clearances and coordinate potential conflicts that would only occur during maximum displacement. Three cheers for technology!

|

| From Drawings |

Laser scanning enabled the 3D model to account for field conditions

|

| From Drawings |

The precision afforded by the model gave trade contractors the confidence to prefabricate larger portions of work thereby reducing overall project cost. 3D model files were converted into electronic shop drawings and sent directly to CNC fabrication machines.

|

| From Drawings |

Excellence in 3D…

|

| From Drawings |

…translated into excellence in the field

|

| From Drawings |

And in the end…

|

| From Drawings |

She turned out even prettier in real life!

| From Aerials |

Discussion

No comments yet.